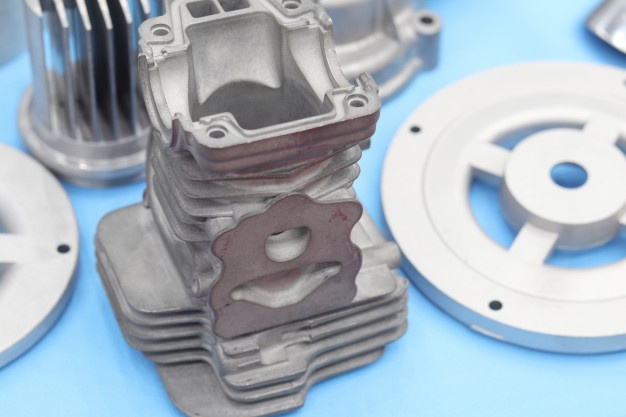

The die casting technique is a tool or machine that can print objects at high pressure by using high heat by injection or injection.

Die casting is casting by force the molten metal into steel mold. The process of die casting techniques is:

The mold is sprayed with the lubricant and closed. The lubricant helps control the die casting temperature and helps in the release of casting.

The molded metal is then injected into the die under high pressure. High pressure makes casting as straight and smooth as dough.

After the cavity is filled, the temperature is maintained until the foundry becomes solid (in this process time is shortened using cooling water).

Then die opened and injection molding is done at high speed so that the entire cavity is filled before any hardened parts, although the design is very difficult to be able to fill very thick parts.

Often operated separation of casting from the rest, using trim die with power press or hydraulic press. This is so that the results are in line with the desired design.

For more information about Die Casting Malaysia, please visit https://stx.com.my/