Computer Numerical Control (CNC) is the use of computer technologies to manipulate conventional machinery. CNC machining has grown more widespread as the usage of computers in industrial production processes has risen. To gain greater control, traditional industrial equipment such as centre lathes, routers, drills, and millers are increasingly controlled by computers.

On the surface, it may appear that a basic computer is operating the machine, but the system’s unique software and control is what truly distinguishes it in CNC machining.

CNC machining is now used in many sectors to help with production since it simplifies the manufacturing process. The following are some of the most significant advantages of CNC machining in manufacturing:

- Improved Efficiency

Efficiency is one motivation for adopting CNC machining in manufacturing. Because computers are used to operate equipment, all key production activities may be automated to enhance manufacturing speed and quality. In contrast, if a CNC machine is not utilised, a technician must drill, which takes more time.

CNC machines do not need to be turned off unless maintenance is required, which means that manufacturing may continue uninterrupted. Humans become fatigued and demand relaxation, which necessitates a pause in productivity. Machines operated by computers do not tyre and do not require breaks, thus the manufacturing process is simplified. Such efficiency is impossible to attain with a manual method.

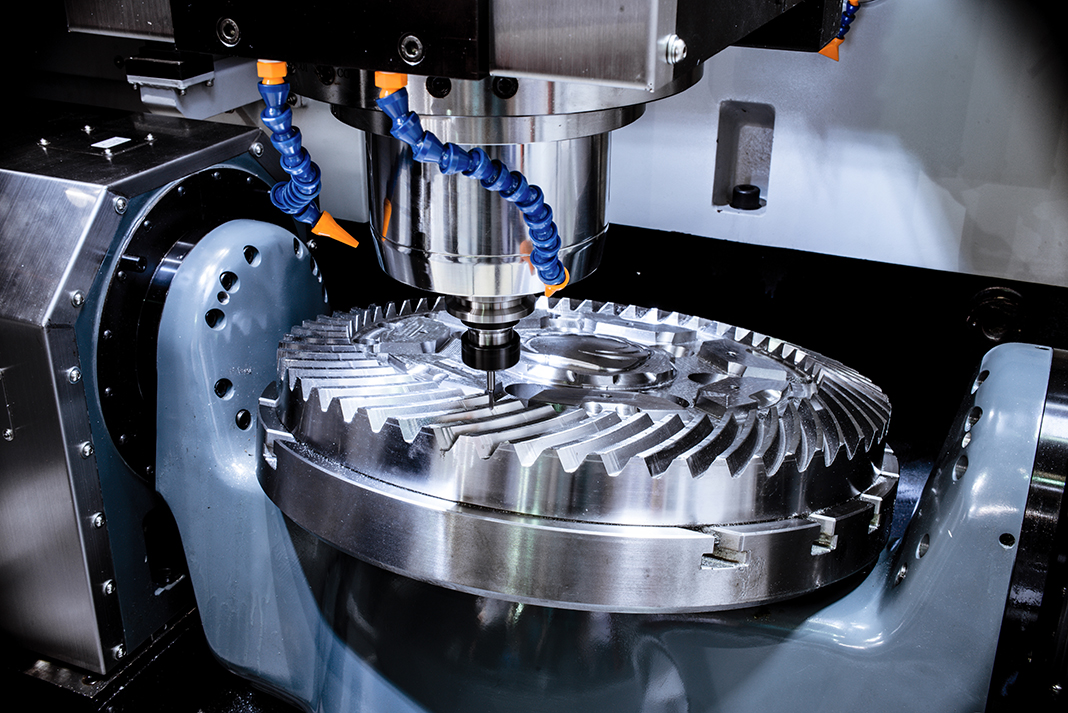

- Greater Precision

Another reason CNC machining is advantageous in the manufacturing industry is its precision. CNC machines may be programmed, and every aspect of the manufacturing process can be supplied into the machine. Identical components may be manufactured with the greatest precision levels utilising CNC machines. When the specifications and designs are programmed into the machine, there is no space for error or mistake.

Error reduction in the production process minimises needless waste. CNC machines can produce perfect parts to satisfy the needs of clients. A high degree of precision also makes it difficult for competitors to copy and steal product designs. CNC machines enable the production of items that would otherwise be difficult to manufacture through manual procedures due to human limitations.

- Fabrication

CNC machines are essential for fabrication. Fabrication involves several processes such as welding metal sheets, shearing, punching holes, and flame cutting, all of which may be done safely using CNC machines. CNC allows for the fabrication of large machines to any specification. CNC machines are reprogrammable and versatile, making them an excellent choice for fabrication.

CNC machining is extremely necessary for production, and it is critical that the machine remains operational or significant losses would occur. However, CNC machines, like any other equipment, wear and tear, and if some elements of a CNC machine get damaged, it might be difficult to locate a replacement.

For more information about Cnc machining malaysia, please visit https://stx.com.my